Portrait

Sonlux – Quality all the way down the line.

Sondershausen is a legendary mining town that today is the site of Germany’s oldest and deepest working potash mine. What’s more, the renowned Loh-Orchester and prominent cultural figures such as Franz Liszt and Max Bruch are inextricably linked with Sondershausen and remain to this day an important part of the city’s heritage.

We’ve been a fixture of Sondershausen for more than 25 years now.

Back in the 1970th the VEB Elektroinstallation produced luminaires at this location. In 1992 Dr. -Ing. Alexander Zimmermann bought the luminair production part of VEB Elektroinstallation and founded the company SONLUX. Since that time we have been producing high-quality and efficient luminaires for industry, trade, authorities and organisations with security tasks as well as event organisers. Since then, the plant, technologies and product range have been continuously expanded. Today, around 130 employees develop and manufacture the SONLUX quality portfolio on 25,000 square meters production area.

"Portable light for professionals" – Innovative premium products with an excellent price-performance ratio.

Quality

Superb craftsmanship.

For us, quality means making no compromises and carrying out our work in a precise, responsible and solution oriented manner.

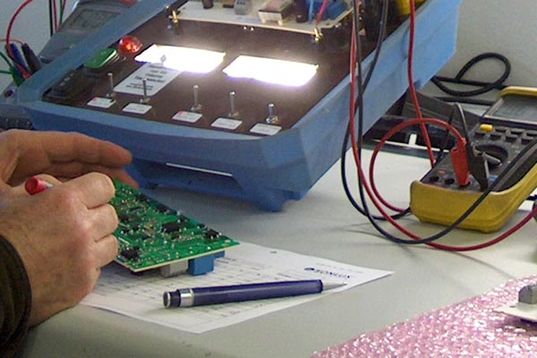

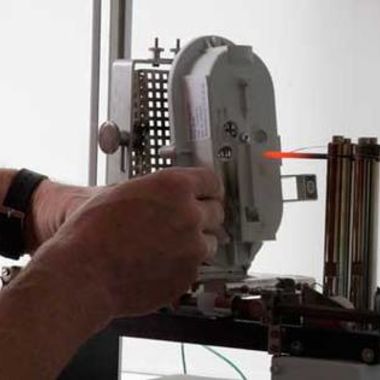

A company that makes more than 50,000 top notch luminaires and luminaire components daily can only guarantee the achievement of consistent quality via one crucial factor: its own desire to get as close as humanly possible to perfection.

Each production process step, from conceptualization to logistics, is subject to rigorous quality control, is continuously optimized, and if necessary is revamped. This unwavering commitment to quality is attested to by the fact that we have been DIN ISO 9001 certified since 2007.

We feel that it is incumbent upon us and our products to meet the highest standards of industrial craftsmanship. But this doesn’t mean that we rest on our laurels – far from it; for we constantly strive to become more productive and efficient. This desire to do better whenever and however we can has been the driving force of our success, which for us means not only complying with standards, but also setting standards worldwide.

Design & Development

The language of product quality.

We feel strongly that one streamlined principle will open up myriad possibilities.

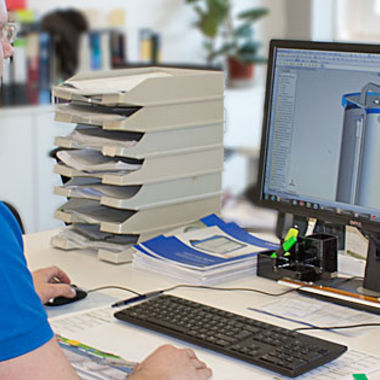

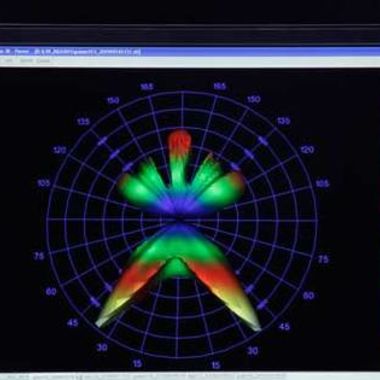

What may at first glance sound easy is in fact the greatest challenge of the product development process: for you can only break the rules if you already know them like the back of your hand. Only if you have mastered the essence can you bring about innovative and inventive change. And only then can you continuously rethink the relationship between form and function and in so doing create an unparalleled interplay between lighting technology, efficiency and product design.

It’s exactly thanks to this approach that one of our workplace luminaires made by SONLUX has attracted great attention: our Gladiator II, which is both “typically functional” and genuinely attractive, has garnered the Best of the Best red dot Design Award, the iF Product Design Award, and the German Design Award. We proudly regard these honors as testimony to the excellence of our products and our commitment to product quality.

The success of our designs is largely attributable to our group’s proprietary R&D department, which integrates a VDE certified lab and a design and innovation department; plus the fact that we often work with outside designers. All of this adds up to what can only be termed the priceless opportunity to shape the future of lighting technology and design.

Environmental Responsibility

More than mere “green” thinking.

We’re pleased to see that concerns such as sustainability, environmental awareness and resource conservation are taking on ever growing importance in today’s world and are prompting many to rethink their practices.

But cogitation and reflection alone are not enough. For we feel it is incumbent upon us, as a manufacturer, to shoulder our ethical and social responsibilities and to take the big picture into very serious consideration in all that we do.

Thus we continuously optimize our lighting and production technologies as well as the use of materials with less environmental impact with the aim of achieving the greatest possible energy and resource efficiency. The entirety of our development and production process centers around cost efficiency and value creation, for nothing protects the environment better and is more environmentally sustainable than timelessly designed long-lasting products.

One important way we put our money where our mouth is when it comes to thinking and acting “green” is that in 2010 our factory in Sondershausen was outfitted with 7,000 square meters of solar panels that provide 244 kilowatt-peak of power and which have been supplying us with most of the energy we need for our factory and offices. These solar panels also reduce carbon emissions by 200,000 kilograms annually.

In October 2017, the lighting of the entire production, warehousing and shipping area was converted to energy-efficient LED luminaires. The annual electricity saving through this conversion is 175,000 kWh, which turns into a saving of approx. 96,000 kg CO2.